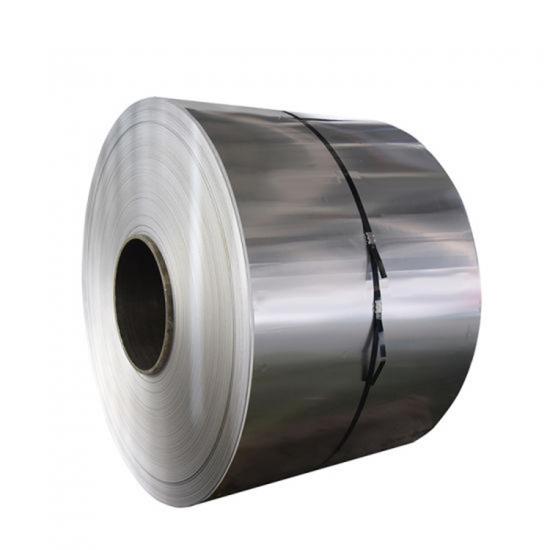

We have long-term coorperation with top premier suppliers. We purchases from premier suppliers offering the best in quality. Our supply partners include the top mills for each of their product groups. A demanding quality and inspection program assures complete compliance to all aerospace and commercial requirements. We supply high-quality steel products that meet all metal needs, including coated steel, color coated steel, electric steel, carbon steel and stainless steel. Our coil & sheet inventory is stocked in master industry sizes.All of these products are fully certified to industry specifications. You can request a quote if you have your specific requirements. We will be glad to help you select the exact grade for your Low Carbon Steel Sheets & Coil. We have large inventories in the specialty alloy metals business. We ship thousands of line items per day cut to size and just in time. So if you are looking for a single item or a complete supply program in specialty metals, we will be glad to help you select the exact grade for your steel sheets & Coil and strip. Whether you are a machine shop owner, contractor, or fabricator, we guarantee that we have the steel products you need. We commit ourselves daily to providing you quality products at a competitive price to your locations.

We supply a variety of coated steel sheet and coil products, including hot-dipped aluminized, galvannealed and galvalume etc. Our value-added service capabilities include slitting, shearing, blanking, stretcher leveling, degreasing and brushing, and metallurgical support. Hot-dip Galvanizing Steel Hot dip Galvanized steel s a process of coating steel with a thin zinc layer, which serves as a corrosion resistant barrier between the steel and the environment. The finish is applied by passing the steel through a molten bath of zinc at a high temperature. Hot-dipped galvanized steel sheet and coil service capabilities include slitting, shearing, blanking, degreasing and brushing, stretcher leveling and metallurgical support. Hot-Dip Galvalume Steel Galvalume steel is carbon steel sheet coated with aluminum-zinc alloy by a continuous hot dip process similar to the galvanizing process. The nominal coating composition is 55% aluminum and 45% zinc. Galvalume combines the excellent barrier corrosion protection of aluminum with the galvanic protection of zinc. The result is a coating that lasts a long time, a coating that provides cut-edge protection along sheared edges, and therefore, a coating that offers excellent protection to steel sheet. It outlasts a galvanized coating of comparable thickness, and offers cut-edge protection that is not available with aluminum-coated sheet. Galvalume steel is recommended when a high level of corrosion resistance is very important: Applications include pre-engineered metal buildings, industrial roofing and siding, air-conditioning equipment, building panels, electrical boxes, farm equipment and machinery, furnace parts, guide rails, heating equipment, and appliances. We inventories a wide range of coated steel. All of these products are fully certified to industry specifications. We can also source to your specific requirements due to our all-encompassing mill supplier relationships. Coated Steel can be manufactured acoording to following standard: ASTM, AISI, SUS, JIS, EN, DIN, GB, ASME, etc As a pre-paint steel supplier, we will be glad to help you select the exact grade for your Low Carbon Steel Sheets & Coil.

Grain-Oriented Electrical Steel Developed from iron-silicon alloys in order to provide low core loss and high permeability, which is necessary for efficient and economical electrical transformers.Features excellent magnetic properties, including high magnetic flux density, low iron loss, and low magnetostriction. Applied typically power transformers, distribution transformers, audio transformers, current and potential transformers, medium to large generators, reactors, and magnetic shields. Available in a wide-range of grades to ensure superior magnetic properties in the rolling direction. Non-Oriented Electrical Steel Developed using a specialized rolling and annealing process, non-oriented electrical steel is an iron-silicon alloy. Non grain oriented steels have good magnetic properties in all directions of the sheet plane. As a result, they are mainly used in electric motors, compressors, reactors for lighting systems and energy meters. Both Grain Oriented Electrical Steel and Non-Grain Oriented Electrical Steel are coated with high dielectric strength surface films that reduce magnetic losses caused by the eddy currents generated in an electrical machine’s core.

Low-carbon steel, also known as plain-carbon steel and Mild Steel contains a small percentage of carbon (0.05–0.25%C). It is the most common form of steel because its price is relatively low while it provides material properties that are acceptable for many uses. In uses where large cross-sections are used to minimize deflection, as in large structures, failure by yield is not a risk so low-carbon steels are the best choice. As a low carbon steel supplier, we will be glad to help you select the exact grade for your Low Carbon Steel Sheets & Coil. Mild Steel can be manufactured acoording to following standard: ASTM, AISI, SUS, JIS, EN, DIN, GB, ASME, etc. We purchases from premier suppliers offering the best in quality. With our experienced processing capabilities, we can produce to your precise dimensions. We are fully capable to service both transactional and contractual requirements with our extensive inventory.

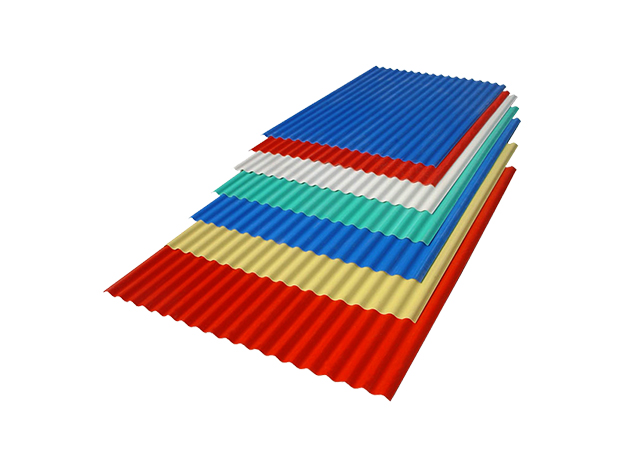

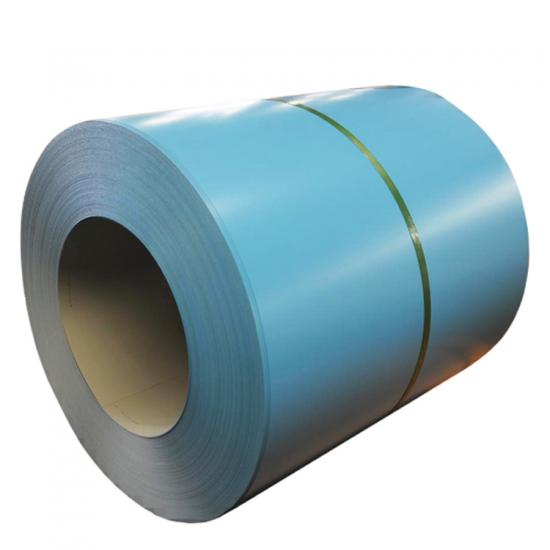

Pre-paint steel is a bare metal substrate or corrosion resistant substrate that has had paint applied to both sides through a continuous coil coating process, which produces a uniform paint finish. The metal is unwound, cleaned and chemically treated during the process. Prepainted steel sheet and coil products protect against corrosion. We supplies a variety of prepainted steel sheet and coil products to meet customer needs. Our value-added service capabilities include slitting, shearing, stretcher leveling, blanking and metallurgical support. As a pre-paint steel supplier, we will be glad to help you select the exact grade for your pre-paint steel Sheets & Coil and strip. Pre-paint steel can be manufactured acoording to following standard: ASTM, AISI, SUS, JIS, EN, DIN, GB, ASME, etc

Steel is an alloy of iron and carbon. Stainless steels are steels containing at least 10.5% chromium, less than 1.2% carbon and other alloying elements. Stainless steel’s corrosion resistance and mechanical properties can be further enhanced by adding other elements, such as nickel, molybdenum, titanium, niobium, manganese, etc. Stainless steel plate steel grades covers four series of Austenitics, Ferritics, Martensitics and Duplex. 304 and 316 stainless steel plate and sheet belongs the austenitic family of stainless steel and they are one of the most versatile and widely used types of stainless plate. Austenitics or 300 series 0.015 to 0.10% carbon, 16 to 21% chromium, 6 to 26% nickel, 0 to 7% molybdenum. The presence of nickel improves corrosion resistance in certain media and makes stainless steel more ductile. The presence of molybdenum further enhances the resistance to corrosion in an acid medium. The most common grades are 304/304L and 316/316L. Austenitics with manganese or 200 series These are chromium manganese steels, with a low nickel content (always below 5%). Ferritics or 400 series: the KARA ferritic offer 0.02 to 0.06% carbon, 10.5 to 30% chromium, 0 to 4% molybdenum. Commonly used internally, these grades are now being developed for envelope and structural products. Austeno-ferritics or Duplex 0.02% carbon, 0 to 4% molybdenum, 1 to 7% nickel and 21 to 26% chromium. These stainless steels not only offer excellent quality, because of their low nickel content – a material that suffers from highly speculative prices – they are also very cost effective. Martensitics 0.1% carbon, 10.5 to 17% chromium. 304 and 316 series are a kind of cheap stainless product and used in many applications. 304 grade has the advantages of low temperature properties and works fine to hardening process by cold working. 304 stainless steel plate has excellent welding characteristics, usually weld annealing is not normally added to maintain performance. 304 stainless steel plate has very good corrosion resistance in a variety of corrosive media. Stainless steel plate can be manufactured acoording to following standard: ASTM, AISI, SUS, JIS, EN, DIN, GB, ASME, etc.

Browse our hot selling products such as cold rolled steel, color coated steel, electrical steel, mild steel, all prepainted products and 300 and 400 series stainless steel products.

Mild Steel Plate is a structural quality steel plate used for a large variety of general construction and industrial applications. A type of carbon steel that contains a low level of carbon, otherwise known as low carbon steel, mild steel contains roughly between 0.05% and 0.25% of carbon by weight. It is not an alloy steel, therefore it does not contain large amounts of anything other than iron and ferrite.

Cold rolled non grain oriented steel is often abbreviated to CRNGO. It usually has a silicon level of 2 to 3.5% and has similar magnetic properties in all directions, i.e., it is isotropic. Mainly used in rotating equipment, for example, electric motors, generators and over frequency and high-frequency converters.

Non-oriented Electrical steel CRNGO fully processed steels are iron-silicon alloys with varying silicon contents and have similar magnetic properties in all directions in plan of the sheet. Non-oriented Electrical steel are principally used for motors, generators, alternators, relays, armatures, and solenoids, ballasts, small Transformers and a variety of other electromagnetic applications.

Galvanized steel sheet refers to a process that covers mild steel with a layer of zinc to provide good corrosion resistance. It is easily formed and easily welded for your best choice when low cost and relatively high strength are required.

Pre-paint steel is a bare metal substrate or corrosion resistant substrate that has had paint applied to both sides through a constant coil coating process, which produces an unchanging paint finish. The metal is relaxed, cleaned, and chemically treated during the procedure. Depending on product specifications, one or both sides may then be primed and coated, oven cured, and rewound for best performance and durability.

304 Stainless Steel is the most widely used of the austenitic (chromium/nickel) stainless steels. In the annealed condition it is essentially non-magnetic and becomes slightly magnetic with the application of cold work. Type 304L Stainless Steel is preferred in welding applications to exclude the formation of chromium carbides during cooling in the heat affected region of the weld. These alloys represent an excellent combination of corrosion resistance and fabricability.

China Colour Coated Coil supplier and manufacturer. Our processing lines produces best quality steel strips, coils and sheets.

Pre-paint steel is a bare metal substrate or corrosion resistant substrate that has had paint applied to both sides through a continuous coil coating process, which produces a uniform paint finish. The metal is unwound, cleaned and chemically treated during the process. Depending on product specifications, one or both sides may then be primed and coated, oven cured and rewound.

Resist corrosion and outlast heat with stainless steel sheet and coil products from WanJuan Steel. WanJuan Stainless steel is a versatile metal offering excellent strength and rust protection at an affordable price point. The metal is easily formed and welded to other metals.

Grain oriented electrical steel is an important material in the production of energy efficient transformers and large, high performance generators. In the form of laminated, wound or punched sheets, it is the essential core material of distribution transformers, power transformers and small transformers.

FUJIAN WANJUAN TECHNOLOGY CO., LTD is a fully-integrated supplier in FuZhou that manufactures, processes and sales highly competitive steel products using the most advanced technology. we manufacture high-complexity steel products that supply the main industries and markets in the region. Our products have been sold to many countries in the world, such as Australia, Germany, France, New Zealand and so on. Our vision is to committed to the development of its clients, at the forefront of industrial parameters and outstanding for the excellence of its human resources. We have an efficient production system. Our facilities feature the whole manufacturing process of steelmaking, from the mining of iron ore to the production of high value added products for the most demanding industries. Our mission is to create value with our clients, improving competitiveness and joint productivity, through a high-efficiency industrial and technological base and a global commercial network. We strive to exceed our customers’ demands and expectations by providing them with the best material and quality of service. With excellence as our primary goal, we provide the best products and services to our customers. Our company is your assurance of quality. Visit Us Now!

15

15

Focus On Steel Industry

10

10

Serve Global Users

We stock a full line of metal products that can be applied in the various areas such as military, construction, industry, petrochemical and etc. Each application material is speically chosen based on its particular strengthness and weakness and can be modified to suit each specific operational requirements.

Copyright © 2024 FUJIAN WANJUAN TECHNOLOGY CO.,LTD.All Rights Reserved. Powered by dyyseo.com

IPv6 network supported

Friendly Links :

Funsomething