304 Stainless Steel is the most widely used of the austenitic (chromium/nickel) stainless steels. In the annealed condition it is essentially non-magnetic and becomes slightly magnetic with the application of cold work. Type 304L Stainless Steel is preferred in welding applications to exclude the formation of chromium carbides during cooling in the heat affected region of the weld. These alloys represent an excellent combination of corrosion resistance and fabricability.

Payment:

T/T,L/CMOQ:

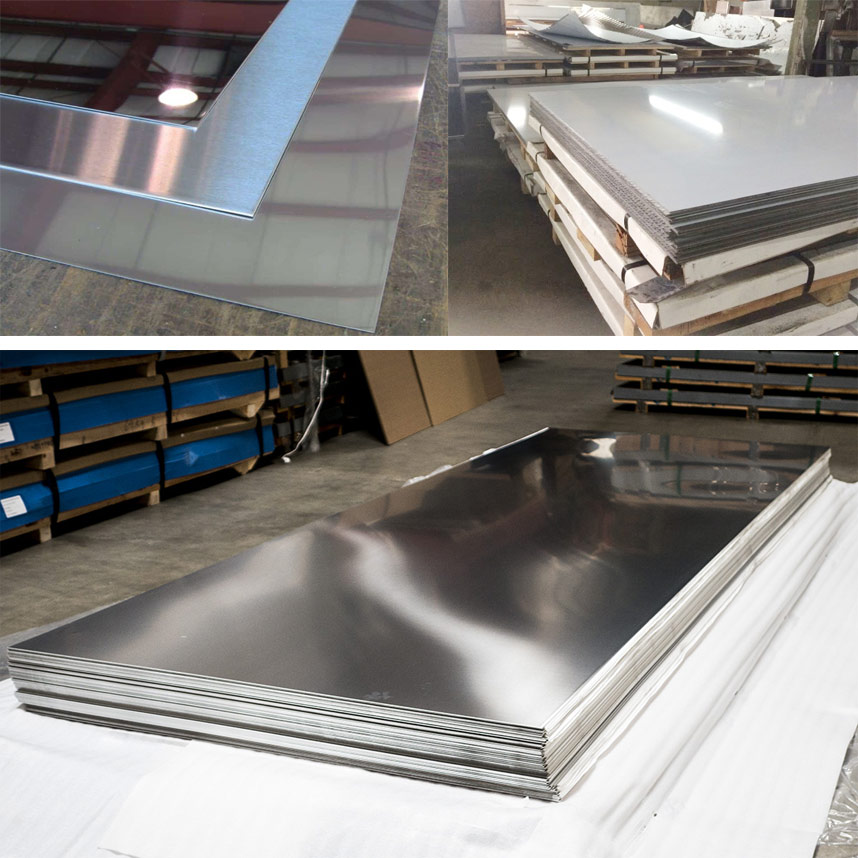

20 tons304/304L Stainless Steel Plate/coil/strip

WanJuan Steel is manufactured to exhibit excellent 304/304L Stainless Steel Plate. We offer both stainless steel plate/coil/strip products in a wealth of different grades and sizes. We manufacture to JIS, ASTM and other standards

Product Information

CHEMICAL COMPOSITION: (PER ASTM A240)

|

Element |

Type 304 |

Type 304L |

|

Carbon |

0.07Max |

0.030 Max |

|

Manganese |

2.00Max |

2.00 Max |

|

Sulfur |

0.030 Max |

0.030 Max |

|

Phosphorus |

0.045 Max |

0.045 Max |

|

Silicon |

0.75 Max |

0.75 Max |

|

Chromium |

17.5 to 19.5 |

18.0 to 20.0 |

|

Nickel |

8.0 to 10.5 |

8.0 to 12.0 |

|

Nitrogen |

0.10 Max |

0.10 Max |

MECHANICAL PROPERTIES: (PER ASTM A240, A666)

|

Type |

Yield Strength 0.2% offset (KSI) |

Tensile Strength (KSI) |

% Elongation(2″ Gauge length) |

|

304 Ann |

30 min. |

75 min. |

40 min. |

|

304 ¼ Hard |

75 min. |

125 min. |

12 min. |

|

304 ½ Hard |

110 min. |

150 min. |

7 min. |

|

304L Ann |

25 min. |

70 min. |

40 min. |

|

304L ¼ Hard |

75 min. |

125 min. |

12 min. |

|

304L ½ Hard |

110 min. |

150 min. |

6 min. |

PHYSICAL PROPERTIES: (ANNEALED)

|

|

|

304 & 304L |

|

Density (lb./ in^2) @ RT |

|

0.29 |

|

Modulus of Elasticity in Tension (psi x 10^6) |

|

28.0 |

|

Specific Heat (BTU/o F/lb.) |

32 to 212 oF |

0.12 |

|

Thermal Conductivity (BTU/hr/ft^2/ft) |

212oF |

9.4 |

|

|

932oF |

12.4 |

|

Mean Coefficient of Thermal Expansion (in. x 10^-6 per o F) |

32 to 212oF |

9.2 |

|

|

32 to 600oF |

9.9 |

|

|

32 to 1,000oF |

10.2 |

|

|

32 to 1,200oF |

10.4 |

|

Electrical Resistivity (micro ohms – cm) |

at 70oF |

72 |

|

Melting Point Range (oF) |

|

2550 to 2650 |

|

Oxidation Resistance – Continuous Service(oF) |

|

1,650 |

|

Oxidation Resistance – Intermittent Service(oF) |

|

1,500 |

Advantages of Stainless Steel

In addition to these environmental benefits, stainless steel is also aesthetically appealing, extremely hygienic, easy to maintain, highly durable and offers a wide variety of aspects. As a result, stainless steel can be found in many everyday objects. It also plays a prominent role in an array of industries, including energy, transportation, building, research, medicine, food and logistics.

Our Service

Advantages to choose us

Previous :

Astm a240 304 Stainless SteelWe values customers needs, so feel free to leave a message and we will reply as soon as possible.

Copyright © 2024 FUJIAN WANJUAN TECHNOLOGY CO.,LTD.All Rights Reserved. Powered by dyyseo.com

IPv6 network supported

Friendly Links :

Funsomething