Stainless steel does not easily corrode, stain, or oxidize/rust. Stainless steel is available in a extensive range of forms, grades, finishes, gauges, widths, and lengths.

Product Orgin:

ShenzhenPayment:

T/T,L/CMOQ:

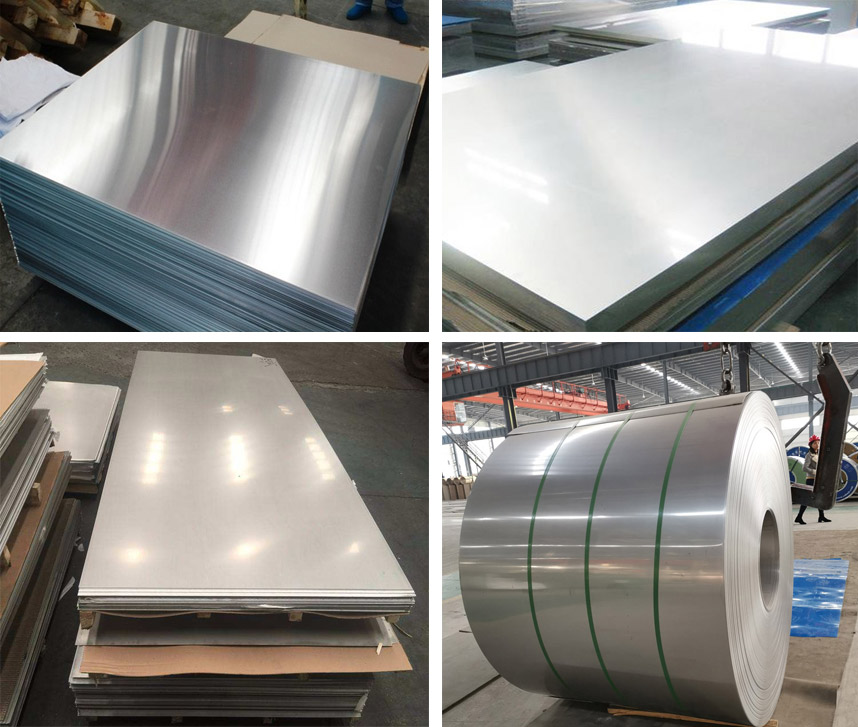

20 tons304N Cold Rolled Stainless Steel Sheet & Coil & Strip

China 304N Cold Rolled Stainless Steel Sheet supplier and manufacture.

Our processing lines produces best quality steel slit coils, strips, coils and sheets.

Product Information

|

Grade |

Euronorm |

China GB |

Japanese JIS |

|

No. |

|||

|

304N |

1.4315 |

0Cr19Ni9N |

SUS304N |

Content of 304N Steel Sheet

|

Grade |

C |

Mn |

Si |

P |

S |

Cr |

Mo |

Ni |

N |

|

|

304N |

Min.Max. |

≤0.08 |

≤2.0 |

≤0.75 |

≤0.045 |

≤0.03 |

18.0~20.0 |

/ |

8.0~10.5 |

0.10~0.16 |

Specification of 304N Steel Sheet

|

Thickness |

4mm-100mm |

|

Width |

1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc |

|

Length |

2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc |

|

Surface |

2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, checkered, embossed, hair line, sand blast, Brush, etching, etc |

|

Finish |

Hot rolled plate (HR), Cold rolled sheet (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated) |

|

Form |

Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Perforated Sheet, Chequered Plate, Strip, Flats,Blank (Circle), Ring (Flange) etc. |

Steel Grade of Stainless Steel

|

Standard |

Steel Grade |

|||

|

Austenitics |

Ferritics |

Martensitics |

Duplex |

|

|

ASTM A-240 |

304,304L,201,203,301,302,303,305,309,310S,316,316L,317L |

409,410s,416,430,434,436,439,441,304,441 |

410,416,420,420C,431,440 |

B2205 |

|

ASME SA-240 |

||||

|

A666 |

||||

Surface Finish & Application

|

2B |

Better surface brightness and flatness improve its mechanical properties,2B could nearly satisfy comprehensive uses |

|

No.3 |

Good brightness with discontinuous coarse stria used as inner and external omaments for building, electrical appliances and kitchen utensils etc |

|

No.4 |

Thinner than NO.3, are used as bathtub buildings inner and extemal omaments electrical appliances food processing and kitchen utensils |

|

BA |

Cold rolled, bright annealed, excellent brightness and food reflexivity like mirror kitchen apparatus, omament etc |

|

8K |

Excellent brightness and prefer reflexivity can be the mirror |

|

HL |

Polished and has continuous streaks, mainly used as buildings omaments elevators, door, frontal plate etc. |

Advantages to choose us

We partner with leading manufacturers to provide cold-rolled, hot-rolled, galvanized, pre-painted, coated and stainless steel for major home appliances.

Quality assured products at competitive price;

High quality assured & competitive price;

Customized service to meet your special requirements;

Our Services

Heavy Gauge Slitting

Steel Coil Slitting

Steel Sheet Cut-to-Length

Electro cold Rolled & Hot Dipped Coating

Steel Sheet & Plate Painting

Finishing Services

Applications

Advantages to choose us

We partner with leading manufacturers to provide cold-rolled, hot-rolled, galvanized, pre-painted, coated and stainless steel for major home appliances.

Quality assured products at competitive price;

High quality assured & competitive price;

Customized service to meet your special requirements;

Applications

We values customers needs, so feel free to leave a message and we will reply as soon as possible.

Copyright © 2024 FUJIAN WANJUAN TECHNOLOGY CO.,LTD.All Rights Reserved. Powered by dyyseo.com

IPv6 network supported

Friendly Links :

Funsomething